5 Reasons Your Hose Keeps Failing

5 Reasons Your Hose Keeps Failing

Written by: Randy Saldivar, Custom Solutions Specialist | March 2020

There are hundreds, if not thousands, of reasons why a hose can fail. Often, the most common failures could have been avoided with proper preparation. Below are the top 5 reasons for hose failure we see in the field.

1. Right Hose, Wrong Application

Hoses generally fail within a few inches of the end connections. Choosing quality, proper end connections and designing a suitable layout eliminates a high percentage of failures. Keep the following in mind when selecting the proper hose for the application: pressure surges what challenge the rated working pressure and avoiding applications with pressure surges or temperatures that exceed the rated limits.

2. Right Application, Wrong Hose

PTFE is one the most chemically inert and compatible materials on Earth. However, use of rubber, metal, or even PTFE-wetted parts in the wrong service can be prevented by checking fluid compatibility with wetter hose materials before installation. PTFE-lined hoses are permeable and mostly unable to achieve more than moderate vacuum service in light gas service.

3. External Damage

Abrasion can occur from a poorly routed hose and will negatively affect the stainless-steel outer braid of PTFE-lined hoses. This drastically reduces the pressure containing capabilities. Consider the least hazardous path for your hose and make use of protective jackets or spring guards. In this picture the outer sleeve has been compromised.

4. Electrostatic Discharge

PTFE is not a good conductor of electricity. Flow of electricity can be impeded when fluids that are good conductors, like steam or fuels, come in contact with each other. Static electricity can be generated by fluid passing through the hose. Because PTFE is non-conductive, it can be modified with sufficient conductivity to ground the static electric charge, eliminating a risk of catastrophic failure from charged particles arcing through the PTFE core.

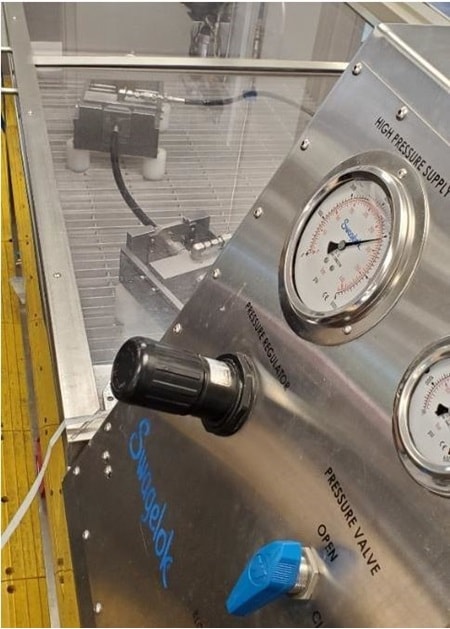

5. Tested Hose Works better

Poor quality components, or choosing a hose solely on low bid, can lead to high costs associated with maintenance, safety, lost fluid, or compromised equipment. You should expect a purchased product to perform well and last long. If there is any doubt, take advantage of a manufacturer's technical support. Choose your hose wisely! Pictured below is a our hose testing chamber.

At Swagelok Georgia | Jacksonville | South Carolina, we work closely with customers regarding hose maintenance and failures, and we know how to protect your hoses, keep your machinery running, and reduce costly downtime. The next time you're walking through your facility, keep an eye out for these sorts of issues and remedy them! Read about our Hose Advisory Services here. If you ever have a questions, reach out to our technical support team! Phone: 678.624.0949 Email: technical.support@georgia.swagelok.com

**Photos used were taken from Hose Advisory Surveys conducted by Swagelok Georgia | Jacksonville | South Carolina. All rights reserved.