Hose Selection Guide

Swagelok Hose – Selection Guide

Written by: Dan Dupler, Swagelok Hose Advisor | November 2019

Selecting the right hose assembly is a crucial step in achieving a leak-free fluid system. Historically, hose assemblies have been treated as a basic item with little regard to proper selection. The typical hose purchase process looks something like this:

- Hose fails

- Maintenance team brings hose to purchasing or storeroom

- Storeroom provides identical hose in length and materials of construction

- Maintenance replaces hose

This process adds costs due to:

- Increase in the number of hoses used (materials)

- Need for additional utilities (air, steam, etc) due to leakage

- Clean-up time costs

- Repair time costs

- Increased downtime

- Finally, and most impactful—decrease yield in production

By selecting the correct hose, you’ll realize the full life of your hose, improving uptime and plant safety while decreasing maintenance costs.

At Swagelok Georgia | Jacksonville | South Carolina, we utilize several different tools to assist our customers in selecting the right hose for their applications. The first step in this process is to use a handy acronym to easily identify if Swagelok manufactures a hose that is right for the job; S.T.A.M.P.E.D.

Let’s look at what S.T.A.M.P.E.D. is and how it can help you with your hose selection:

Size

Temperature of the system

Application

Media (for material compatibility)

Pressure

End Connections

Delivery/Availability

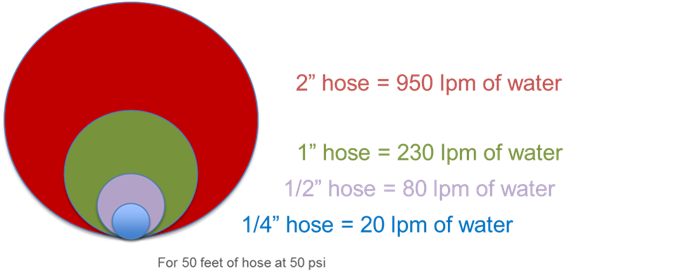

Size

How much flow does the application require? Figure 1 shows the importance of selecting the correct ID of the hose:

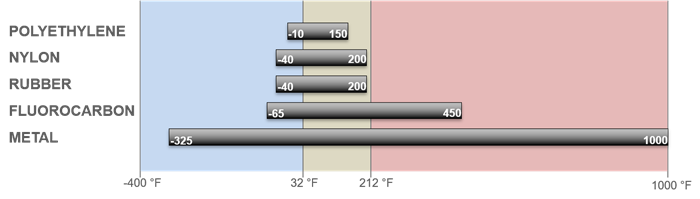

Temperature of the system

What is the minimum and maximum temperature the hose will be exposed?

Application

Is this hose moving or does it remain relatively stable? Does conductive media run through the hose at high velocity? Is there outside factors such as ambient temperatures or operator handling that could cause early failure?

Media (for material compatibility)

Does the media being conveyed present any materials compatability with either the internal core tube or the end connections? Is there a concern of fluid permeation?

Pressure

Are the hose materials of construction compatible with the pressures (vacuum or positive) experienced by your system?

End Connections

What are the endpoints that your hose is connecting to? The goal of selecting end connections is to provide an easy solution for maintenance to take out and insert hoses into. For example, a hose with Male National Pipe Thread (NPT) presents issues when going to assemble as tightening one end connection causes the other to loosen.

Delivery/Availability

What is the needs date for your hose solution? Swagelok carries a wide variety of hose types, sizes, and end connections to best serve our customers.

Swagelok Georgia | Jacksonville | South Carolina is eager to assist in building the right hose assembly for your application. We’re striving to spread awareness that flex hoses are highly-engineered, critical components that have immediate impact on the integrity of your most important processes. We’re here to help!

For further help in hose selection or if you have any questions, email Dan Dupler.

*All images taken from Swagelok Hose Selection Slide Show