How Much Could a Leak Detection Survey Save You?

How Much Could a Leak Detection Survey Save You?

Written by: Scott Mooney, Business Development | June 2020

Swagelok Georgia | Jacksonville | South Carolina has conducted various Fluid Systems Evaluations and Audit services at customer facilities to find and solve problems and help them operate more safely and efficiently. One of the more common surveys conducted is our Compressed Gas Leak Detection Survey where we identify and tag gas (air, nitrogen, steam, etc.) leaks in a predetermined area of your facility.

A Local Combined Cycle Power Plant (500MW) recently requested we perform a Compressed Gas Survey in their water plant building, focusing on their instrument air system. They had been dealing with the problem for several years and were experiencing pretty significant instrument air leaks caused by the corrosion from the NaOH in the atmosphere.

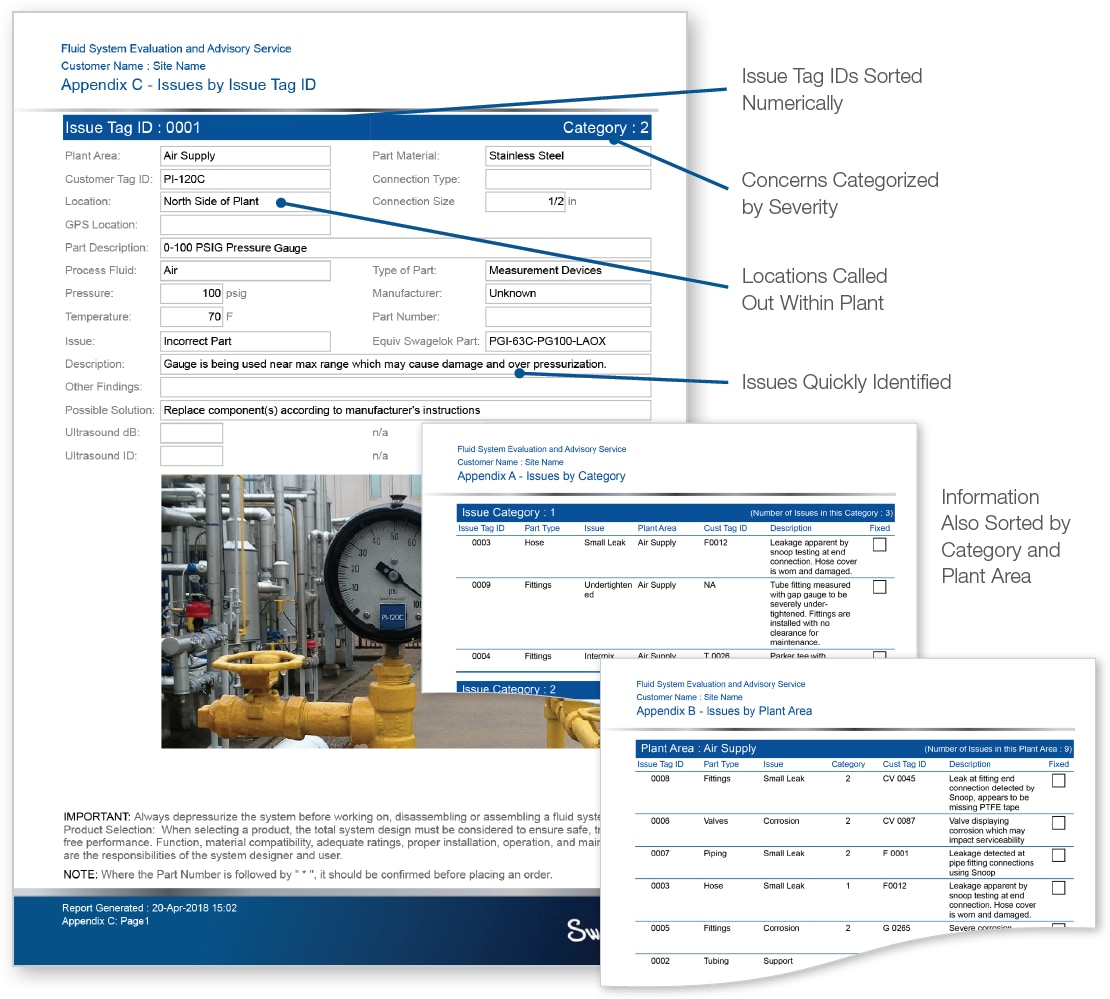

Two of the plants senior E&I Technicians brought this issue to the Plant Manager, requesting a Compressed Gas Survey on the enclosed building. The Compressed Gas Survey report entails:

- Each leak is tagged

- List and location of leaks (Including size)

- Types of leaks

- Annual costs due to the leaks

- Recommended solutions

- A complete written report with all of the above findings

After a 5 hour survey finding dozens of leaks costing them nearly $17,000 cost every year, we presented the finding to the Plant Manager, Operations Manager, and Maintenance Manager. The Plant Manager was so impressed with the report, that he used it to justify the capital expense needed to fix the system.

Compressed Gas Leak Detection Report Sample