Basic Pipe Threads Explained

Basic Pipe Threads Explained

Written by: Don Lloyd, Director of Technical Applications | November 2019

OVERVIEW AND INTRODUCTION

Positive sealing of threads can depend on many variables: Installation torque, system operating pressures, specific gravity - viscosity of the system media, component material, cleanliness and quality of the thread, and temperature are some of these variables.

The type of thread used to make a connection can have an impact on seal integrity. For the purpose of this communication, we will review National Pipe Tapered (commonly known as NPT), International Standards Organization (ISO) 7/1 (British Standard Pipe Tapered), International Standard Organization (ISO) 228/1 British Standard Pipe Parallel, and the Society of Automotive Engineers (SAE)/MS) Internal Straight Thread Boss (parallel). Although there are other types of connections worldwide, these thread configurations (NPT, ISO, SAE) are the most common fitting connections seen on instrumentation and small-bore process systems.

BRIEF HISTORY TAPERED PIPE THREADS

National Pipe Thread / NPT (Taper) has been the American standard for making up pipe connections since the 1850’s and is still a common choice today. International Standards Organization (ISO Taper) also has its roots dating back to the middle 1800’s, created for use by the British Empire. When properly manufactured and assembled, the seal takes place between the third and fifth thread.

TAPERED VERSUS PARALLEL THREADS

Tapered Pipe Threads are applied at an angle, typically 1° 47’ to the centerline of the fitting. Tapered threads are designed to seal between the flanks of the threads, but manufacturing tolerances and truncation limits for crests and roots of the fitting do not usually create a leak-tight seal. Tapered pipe threads work by interference fit and will require a sealant to make a leak tight seal. A good sealant is always required to fill the gaps between the roots and crests and to prevent system media from passing through the connection. A good thread sealant will also act as an anti-galling lubricant between the sealing surfaces. Tapered pipe threads, whether they be NPT or ISO, are known as dynamic threads. Sealing is accomplished by thread distortion.

Parallel Pipe Threads (also referenced as straight threads) are applied parallel to the centerline of the fitting. Different from tapered threads which seal on the flanks of the threads, there is no interference between the crests, flanks, and roots of the parallel threads. A gasket (all metal or composite) or O-ring is normally used to seal parallel pipe thread connections. No Teflon tape or sealant is utilized on these threads. There may be, however, certain applications where the installer may wish to utilize a compatible lubricant to reduce galling of these threads. Parallel threads are also known as mechanical threads.

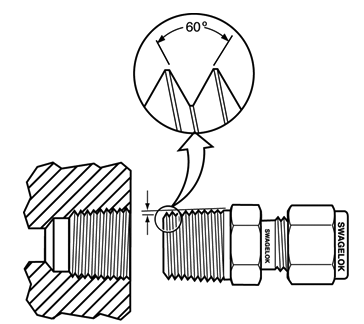

NPT (Tapered Thread)

Thread taper = 1° 47’

The truncated areas of the roots and crests are flat

Pitch is measured in threads per inch (TPI)

60° thread angle

Standards are: ANSI/ASME B1.20.1, SAE AS71051

Some type of pipe thread sealant is always required when making up tapered threads.

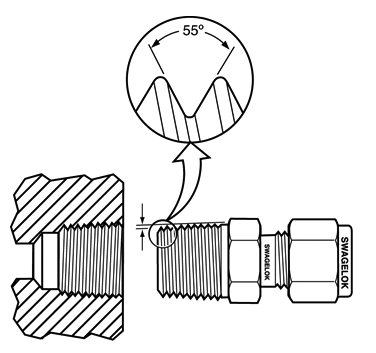

ISO 7/1 (British Standard Pipe Taper, Whitworth)

Thread Taper = 1° 47’

The truncated regions of crests and roots are rounded

Pitch is typically measured in threads per inch (TPI)

55° thread angle

Standards are: BS EN 10226-1, JIS B0203, BS 21, DIN 2999

ISO tapered threads are equivalent to DIN 2999, BSPT, and JIS B0203.

A pipe thread sealant is always required when making up tapered threads.

CAUTION - NOTE: ISO tapered threads are utilized in a similar way to NPT threads. It is important that ISO and NPT threads are not intermixed. ISO threads have a 55° angle compared with the 60° angle for NPT. ISO Thread pitch can be measured in millimeters but can also be stated in inches. In many cases, the number of threads per inch is different, and the crest and root dimensions are different from NPT.

Watch this video on tapered pipe thread installation with Teflon tape:

ISO 228/1 (British Standard Pipe Parallel, Whitworth)

Pitch typically measured in threads per inch (TPI)

The truncated regions of crests and roots are rounded.

55° Pitch Angle

Standards are: JIS B0202, BSPP

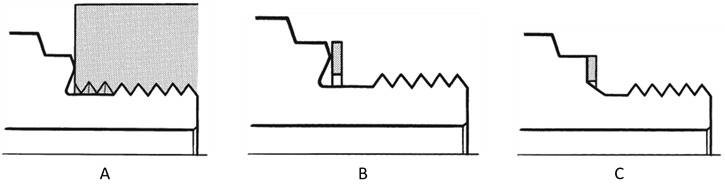

ISO parallel threads are equivalent to DIN ISO 228/1, BSPP, and JIS B0202. ISO Parallel threads are similar in design to 7/1 threads except there is no taper and there is no interference like the tapered pipe threads of ISO 7/1 or NPT. An O-ring or gasket is normally utilized to seal into the parallel female threaded component. Threads of this type typically provide excellent seal and reseal capability.

Each of these shows an ISO 228/1 seal: A shows without a gasket, B with a metal gasket, and C with a composite gasket.

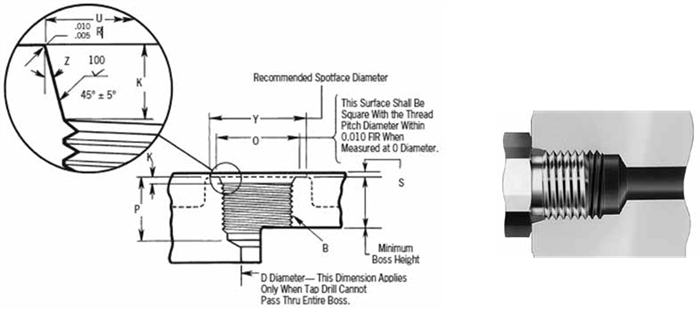

SAE / Unified Screw Threads

60° thread angle

Pitch is measured in inches

The truncated areas of the crest and root are flat

Diameter measured in inches

Unified screw threads are typically utilized in the hydraulics industry and in military hardware.

SAE/MS straight thread fittings are used to seal to SAE/MS ports by utilizing elastomeric O-rings.

Threads of this type typically provide excellent seal and reseal capability.

Male fitting with an O-ring (second figure)

In review, there are many types of threaded connections in the world. We have reviewed several of the more common fitting configurations. To properly make up pipe fittings, we must use high quality products, correctly identify the type and size we are working with, determine if a sealant or gasket is required, maintain cleanliness, and install utilizing the appropriate instructions.

For more information: contact Don Lloyd or request a copy of the Thread Identification Guide.