Regulator Blog_MS

Regulators 101: Four Things You Need to Know

Written by Mark Starnes, Account Manager | July 2020

Walk through any industrial facility today and you will see several varieties of Pressure Regulators in various applications. Some are made of a plastic material, some are large, and some are small…all performing a similar function, Pressure Control.

With so many types and sizes available to perform one function, it is quite intimidating when tasked to choose the right regulator for a system upgrade or new design. The primary consideration, for many, should be how accurate must the pressure control be for the application and will it perform under future system upgrades or changing system parameters.

Understanding the importance of pressure control accuracy as a primary consideration makes the search and selection for the proper regulator easier. Most regulator manufacturers publish their accuracy percentage in their product literature, and of course with the higher percentage of accuracy, so goes the price. Failing to know the accuracy requirements could affect system function and lead to losses due to poor product quality or even unexpected downtime.

What affects control accuracy in a regulator?

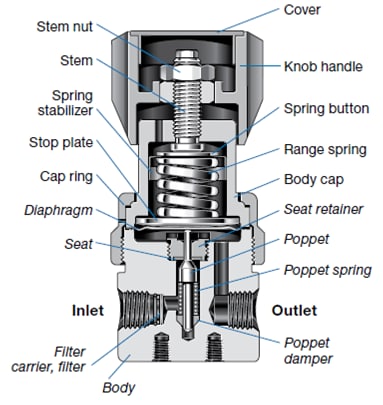

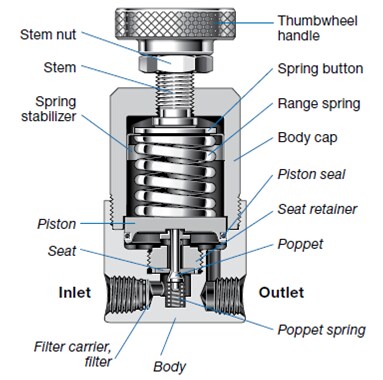

A regulator controls pressure by balancing forces between a high inlet pressure and a lower outlet pressure. Accuracy is determined by how these forces are balanced using a control spring against a diaphragm or a piston, and how well these components are paired in the regulator’s construction.

What if I must regulate pressure from a very high pressure source to a very low pressure system?

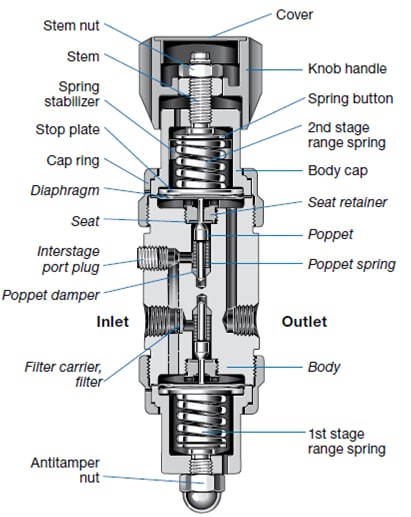

These applications usually require a 2-stage regulator for best accuracy results. A common use is regulating pressure from a gas bottle, (usually at 2200-3600 psi) down to an analyzer that requires a very low pressure, (usually 10-50 psi). The better fit here is to use a 2-stage regulator that is essentially 2 single stage regulators in series but bundled into a single unit

Here the high pressure inlet is regulated typically to 500 psi and then sent to the second stage where the finer control spring and diaphragm produces the desired lower analyzer pressure. This step down approach allows for a more narrow span between the inlet pressure and the desired outlet pressure and puts less demand on the control spring’s role in balance of forces.

Why is the control spring range selection important?

The typical rule is to select a control spring range where the desired outlet pressure is in the middle of that range. An example is if the analyzer needs to have gas coming in at 25 psi. A control spring range of 0-50 is the preferred, with the desired pressure falling roughly in the middle, where the spring forces are most accurate. Often, many will overlook this detail and select a control spring range of 0-100 thinking this will fit. Actually, the regulator’s accuracy is compromised as the spring can only operate in the lower 20% of the spring force capacity.

What if I want to add several analyzers to the same regulated gas source?

When additional demand, or in this case where more gas flow is required to feed additional instruments, two things can happen: one is supply pressure effect (SPE) and the other is Droop. Avoiding these two phenomena is critical to accuracy and overall function. Ignoring these possibilities may lead to inaccurate instrument function and results, as well as potentially damaging expensive equipment. Properly sizing a regulator can help avoid these situations.

To better understand these points and to see more on how regulators play an important role in reliable pressure control, please see the link below for our short, Regulator Basics Webinar. Field Engineer, Ben Carr, goes more in depth on important topics like: theory of operation, key terms, and sizing a regulator.

Learn more here: Watch Our Regulator Webinar

Do you have more questions? Reach out to your account manager or contact us.